Showroom

CNC Grinding Machines are utilized for the purpose of finishing metal components with great precision and high precision production. The CNC automation applies in grinding process, which enables consistency and precisely detailed designs so that machines can be trusted by industries, including automotive, aerospace, and tool-making sectors.

Cylindrical Grinding Machine is a precision machine tool that is used for grinding cylindrical surfaces. This type of machine is used for metal workpieces to create fine finishes or to shape them with much precision. It is applied for grinding either external or internal surfaces of the cylindrical part. Grind cylindrical parts after extraneous processes like turning or casting, with an aim to have tight tolerances and surface finishes.

Grinding Machines are necessary and highly utilized manufacturing and metalworking machines in shops that offer acceptable fine finish, precise dimensions, and smooth surface on parts or workpieces. Also, with these machines, many forms of material such as metals, plastics, and ceramics may be shaped, sharpened, finished, and polished. In this type of machine, an abrasive wheel or belt removes material from a workpiece through a grinding process.

CNC Grinding Machines are highly accurate, versatile, and efficient in finishing workpieces of parts with minimal human interaction to very tight tolerances. The precision offered by CNC grinding is critical for high-performance applications in aerospace, medical devices, and automotive components. Automated systems improve the quality, consistency, and efficiency of grinding while preventing over-grinding, which would otherwise be common in manufacturing lines requiring high accuracy with complex geometries.

Cylindrical Grinder Machines are one of the very important tooling in manufacturing and metal working that can help grind out cylindrical surfaces of workpieces. It's widely applied in making automobile, aerospace, medicinal, and tooling components such as shafts, rollers, spindles, and gears. This machine is capable of accurately grinding both outer and inner diameters of any cylindrical part with close dimensions and smooth surface finishes and tight tolerances.

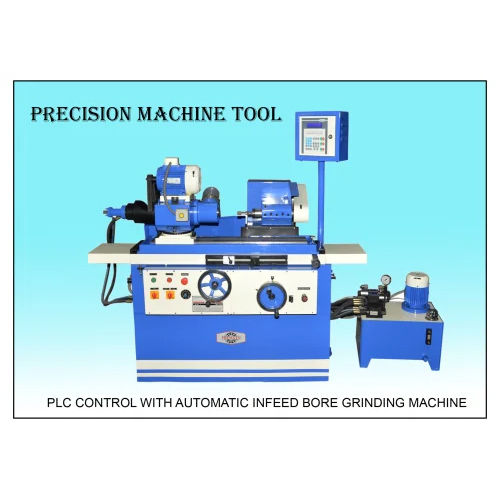

PLC Cylindrical Grinding Machines is an industrial computer that controls the automation of electromechanical processes such as machinery on a factory's assembly line, amusement rides, or even light fixtures. Highly recommended for industries that have the need to mass produce precise parts, such as automobile and aeronautic industries and medical appliances. It can monitor, alter, and adjust grinding parameters in real-time to achieve very precise cylindrical external and internal part grinding.

A Hydraulic Cylindrical Grinding Machine is such a kind of cylindrical grinding machine where hydraulic systems have been provided to make the feeding workpiece, movement of grinding wheel, and other operations fully automatic. It makes it possible to provide smooth, controlled motion to both the workpiece and the grinding wheel with better precision and surface finishes. These machines are used widely in industries such as automotive, aerospace, medical, and tooling for producing parts in high tolerance quality with fine finishes.

Grinding Machine's Spare Parts rely on numerous spare parts to maintain their performance, precision, and reliability. Common spare parts include grinding wheels, spindles, bearings, feed mechanisms, coolant systems, and electrical components, all of which contribute to the accuracy and efficiency of grinding operations. Routine maintenance and the timely replacement of worn or damaged parts are essential to ensuring the continued functionality and longevity of the machine.

Turcite Sheet is basically a material that self-lubricates, and it is primarily used in machinery manufacturing where friction goes minimal in sliding applications. It has been produced using PTFE or a mix of PTFE with other ingredients, which can include fiberglass or graphite to provide strength and wear resistance. Turcite materials do have loads of performance advantages and durability, making them the best for a very wide range of sectors-from cars to aeronautical machines to heavy machinery.

Back to top

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese