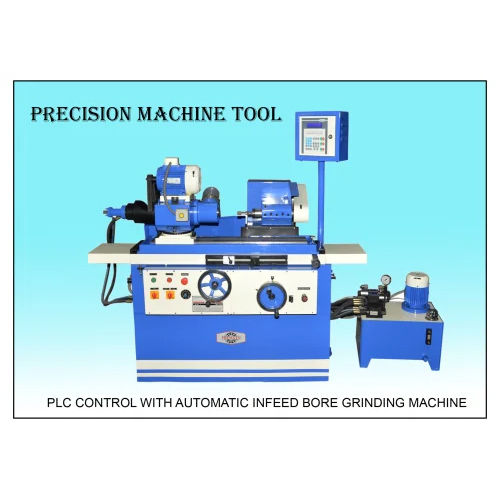

PLC Controlled Internal Bore Grinding Machines

950000.00 आईएनआर/टुकड़ा

उत्पाद विवरण:

- प्रॉडक्ट टाइप Internal Bore Grinding Machines

- सामान्य उपयोग Industrial

- वजन (किग्रा) किलोग्राम (kg)

- ऑटोमेटिक

- फ़ीचर

- रंग

- वारंटी Yes

- अधिक देखने के लिए क्लिक करें

X

मूल्य और मात्रा

- 1

उत्पाद की विशेषताएं

- Yes

- किलोग्राम (kg)

- Internal Bore Grinding Machines

- Industrial

व्यापार सूचना

- दिन

उत्पाद वर्णन

Internal Bore Grinding Machines is a precision tool designed for machining the inside diameter of cylindrical workpieces. This specialized equipment is crucial for industries like automotive, aerospace, and tool manufacturing. It ensures high accuracy and surface finish, allowing for the creation of precise components such as engine cylinders, hydraulic cylinders, and injection molds. Internal bore grinding machines come in various sizes and configurations, catering to diverse machining needs and production requirements. The efficiency and reliability make Internal Bore Grinding Machine a valuable asset in modern manufacturing operations.

| Type of Grinding Machine | Internal Grinding Machine |

| Grinding Wheel Diameter | 40 mm |

| Max. Internal Grinding Length (mm) | 300 / 500 / 800 / 1000 / 1200 / 1500 / 2000 mm |

| Grinding Material | Metal |

| Max. Workpiece Length (mm) | 300 / 500 / 800 / 1000 / 1200 / 1500 / 2000 mm |

| Automation Grade | Semi-Automatic |

| Max. Grinding Length (mm) | 300 / 500 / 800 / 1000 / 1200 / 1500 / 2000 mm |

| Job Material | Metal |

| Max. Grinding Wheel Speed (rpm) | 1700 to 1900 rpm |

| Grinding Wheel/Spindle Motor Power (HP/W) | 5 / 7.5 hp |

| X-axis Feed Speed (m/min) | 0.1 to 0.4 mtr. / min |

| Z-axis Feed Speed (m/min) | 2000 mm / per min |

| Max. Table Load (kg) | 80 to 200 Kg |

| Weight | 2300 kg Approx. |

| Shipping Volume | 6 ft x 6ft x 7 ft |

| Country of Origin | Made in India |

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

Back to top

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese